All Rights Reserved © 2025 | Design & Development by Ariadna Romero

ABOUT US

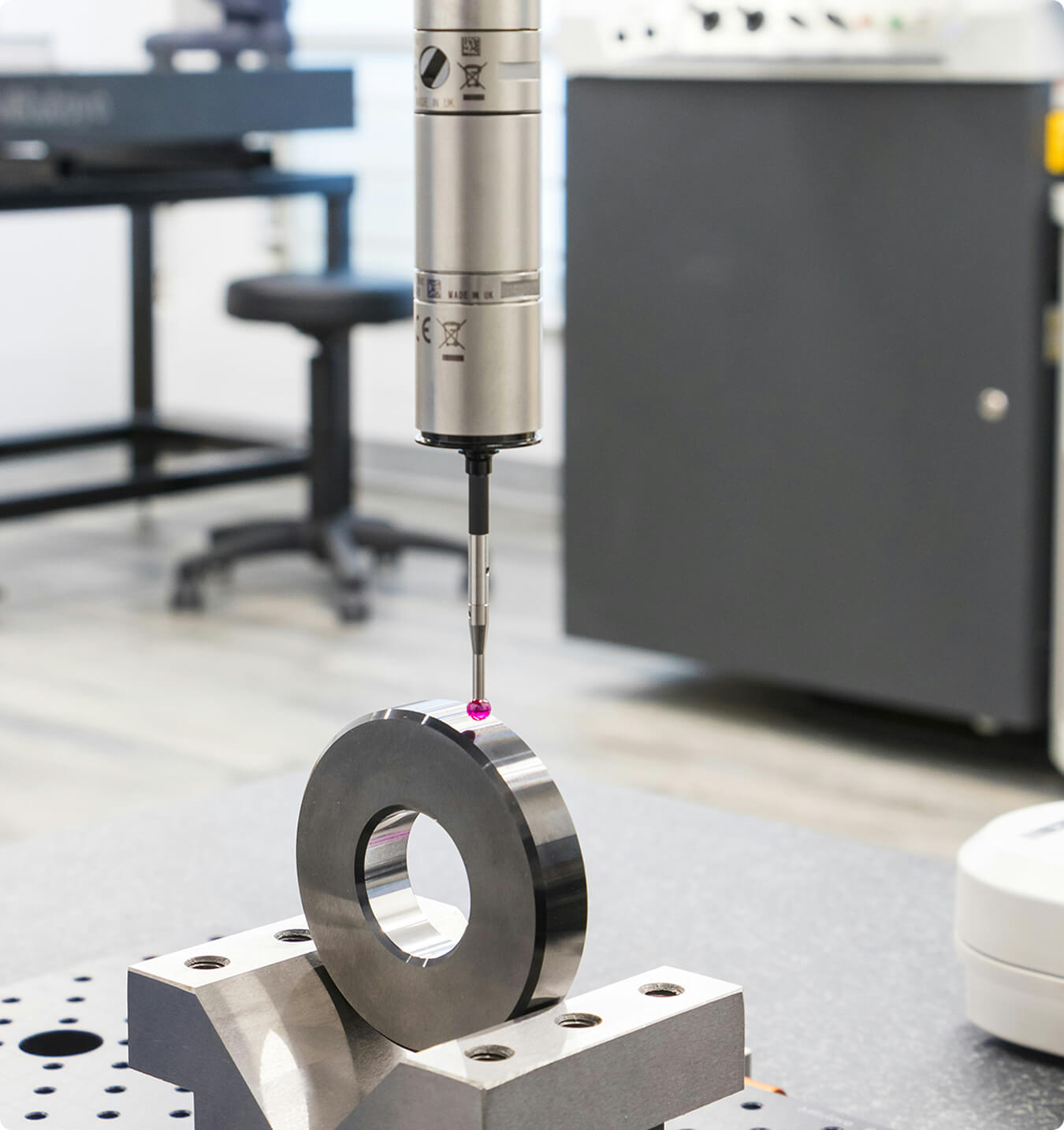

Blake Group is a well established and respected business, known for its reputation for quality and service in the steel fabrication and engineering industries.

Blake Group was founded in 1938 by James Blake and was originally known as James Blake & Co (Engineers) Limited and is still registered under that name at SC036390.

Leading industry and lobbying for best practice standards, Blake Group is an active member of a number of institutions and associations including:

Capabilities and Expertise

OUR CAPABILITIES INCLUDE

17tn

Mobile crane

220tn

4m Amada bake press

150tn

Press brakes

3x10m

Guillotine cutting

Engineering Consultancy

We cover a variety of matters from the legal issues of oil storage to steel manufacturing production matters.

01 Oil Storage Consultancy Services

02 Fabrication and Metalwork Consultancy Services

Engineering Innovation & Development

Always able to turn his hand to any engineering challenge, as a young man James Blake quickly became established as a respected craftsman in his trade.

It is with a continued growing reputation for quality and service, predominantly through word of mouth, that the firm sits proudly at the forefront of Scottish heavy engineering today.

Blake Group has thrived on what it calls ‘solutions-driven engineering’ taking the wealth of experience gained over 85 years and applying it to client projects.

Senior management all come from a mechanical engineering background so client projects are handled by experts from the initial consultation stage or site visit. Almost all projects undertaken are bespoke and inevitably design challenges will arise, however Blake Group use this as its point of difference to add value through its Consultancy Services.

Working closely with clients, the firm approach projects with confidence, sometimes recommending approaches outwith our brief to achieve the best possible outcome like focus on what’s achievable, safe and where budget is crucial, affordable. This realistic approach combined with creative and innovative thinking streamlines the manufacturing process with cost saving outcomes that reduce risks.